Mark Hammar

Mark Hammar

November 18, 2014

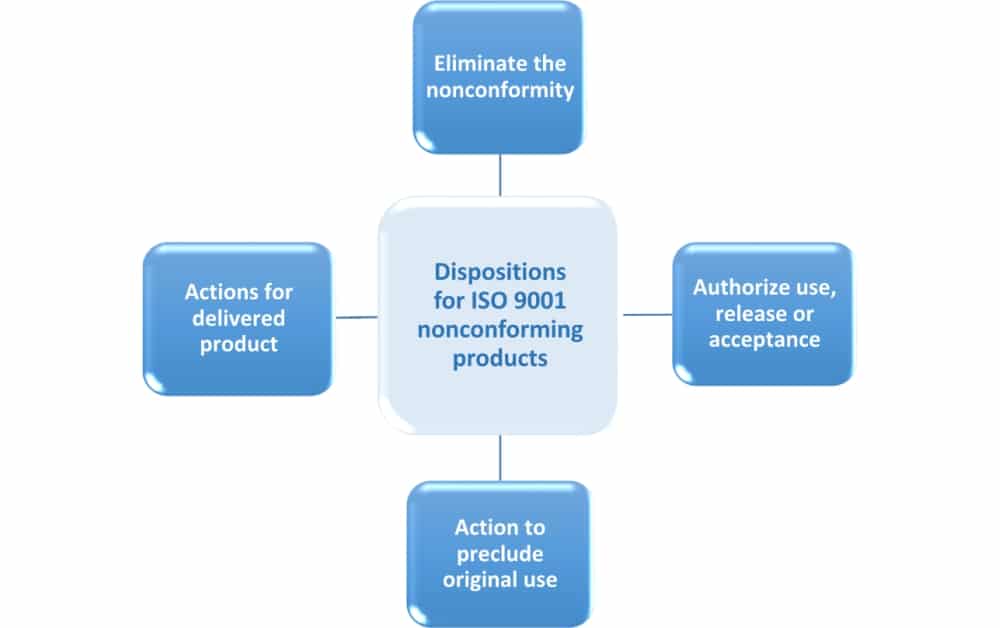

ISO 9001 section 8.3 on control of nonconforming product identifies four ways that you can deal with the nonconforming product, but what do these sentences mean? Many companies call this action of identifying what to do with each nonconforming product the “disposition” of the nonconforming product. The disposition identifies what needs to happen to the product either to make it useful, or to dispose of it. For some more information on the process for non-conforming material, see this blog post on Five steps for ISO 9001 nonconforming products. Here are explanations of what the standard means, and some common words used for the dispositions:

ISO 9001 states that you can “take action to eliminate the detected nonconformity,” which is often called “Rework.” By performing rework on nonconforming product, you will return it fully to the intended state. If you have a bracket that has holes drilled too small, you can rework the bracket to make the holes the right size, making it fully functional. If a service supplied to a customer is not satisfactory because it is missing a promised component, this component can be added to make the service what was promised. When rework happens there is an additional requirement later in the clause to re-verify and demonstrate conformity after the nonconformity is corrected.

This is often referred to as Use As Is (UAI) when you “authorize the use, release or acceptance under concession by a relevant authority and, where applicable, by the customer.” If the product or service does not fully conform to the intended requirements, but it can still be used with acceptable degraded results, then this can be approved by an appropriate person, who might be the end customer, if needed. An example might be a bracket that has three holes drilled instead of two, but the third hole does not interfere with the assembly, so the part is used because it will not affect the product.

A unique combination of these first two dispositions is sometimes called a “Repair,” and is often confused with a rework. With a repair you perform actions on the nonconforming product or service that do not fully correct it, but make it acceptable to be used as is. An example would be a bracket with a hole out of place, which could have a third hole added in the correct position so that it could be used, or a service which cannot be fully delivered because a component is not available, but an alternate component is substituted that is acceptable to the customer.

The main way of “taking action to preclude original intended use or application” is to destroy the part in question, often called “scrap.” When you scrap a part you will do what you need to in order to make sure it is not used, and some industries require the part to be defaced or destroyed. What is important is that you have a way to make sure it is not used if you decide on this disposition.

Another method that is sometimes used is to find an alternate use for the item from the one originally identified, and this is often called downgrading. An example of this is when a resistor is downgraded to a lower-grade component, or when a clothing store offers “seconds” of a clothing line that have minor flaws that allow the article to remain usable.

The standard describes this as “taking action appropriate to the effects, or potential effect, of the nonconformity when nonconforming product is detected after delivery or use has started.” This is where your company has delivered a product or service and finds that there is a problem with it either through your own means or when detected by the customer. There are many things that fall under this heading, such as “customer returns,” “product recalls,” “partial or full refunds,” or “customer notifications.”

It is important to note that there is a decision required on what is appropriate depending on the effects of the nonconformity. For instance, if there is a defect discovered in software (a software bug) that is determined to be unnoticeable by the end user, it may not be addressed at all. However, if a mechanical failure can cause a car to catch on fire, even if this has not yet happened, then the problem should be addressed.

Not everyone has a use for “seconds,” and not all industries will allow for repairs. It is important that your company identifies in your procedure what methods of disposition you will allow for your nonconforming product or service. The list in ISO 9001 is not intended to be the list that all companies must include; it is stated that you shall deal with nonconforming product by “one or more of the following ways.” If your industry has a simple decision of use if it is good, or scrap if it is not, then the other disposition classifications do not apply to you. Identify what you will do with nonconforming product; then ensure that you follow your process.

Enroll in this free online training: ISO 9001 Foundations Course to learn more about corrective actions.