One of the most critical processes for managing your aerospace Quality Management System (QMS) is the internal audit, which is an important element within the AS9100 Rev D standard. Although the process is well understood, as is described in the article 6 Main steps in the internal audit according to AS9100 Rev D, there is not a consensus regarding the best way to create the internal audit checklists that are developed when preparing for an audit.

There are, however, a few important things to remember when preparing these documents in order to make sure they are useful to the auditor and to ensure a successful audit:

Review of any process documents

Because the purpose of the audit is to compare what is actually happening in the audit with the planned arrangements, any process audit checklist will start by reviewing the planned arrangements for the process, and when there is a documented procedure for the process, this is where it is recorded. When reviewing the documents, be sure to consider:

- Updates and improvements: If any changes have happened in the process, it is important to follow up to make sure that the change was communicated adequately and is in use. This is especially important if the change was due to a problem that occurred, in order to prevent its recurrence.

- Unchanged content: Especially if the content of the process has not been updated for a long time, some attention should be paid to reviewing if this is still accurate. Sometimes, employees can find a more efficient way to do things, and if updating the procedure is forgotten, the best practices on the floor may not be reflected in the written documents.

- Previous corrective actions: One important thing to review is any corrective actions identified for the process, especially those found in previous audits. Part of your checklist will need to include checks that these corrective actions were adequately implemented, properly communicated, and that you can verify that they are effective in addressing the problem previously found.

Audit checklist preparation

The audit checklist is simply a list of information to check and questions that the auditor wants to ask during the audit in order to verify that the process outputs are meeting the planned arrangements for the process. While many of these questions come from the documentation review, there are a few other areas that can be important considerations, especially if there is no documented procedure for the process:

- AS9100 Rev D requirements: If the process is documented, then this should have already been checked when the document was approved, but it is important to verify every so often that your processes have not strayed from the requirements of the standard. It is imperative that you maintain alignment with the AS9100 requirements, and verifying this during internal audits is a good way to do this.

- Process inputs and outputs: A process is any activity that takes one or more inputs and creates one or more outputs, and often the output of one process will become the input to another process. This being the case, there can be many problems that arise through the interactions of processes, and reviewing these interactions is important during internal audits. Are the outputs complete and accurate as needed by the next process? Is the output even used, and if not, why is it created? This can be an important area for finding cost and time savings in processes.

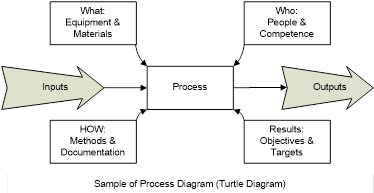

- An overview of the process: Especially when no documentation exists, creating and reviewing an overview of the process can be useful. When the process approach was first introduced, many auditors used a diagram – often called the “turtle diagram” (some people think it looks like a turtle) – to understand how a process worked. To use this diagram, focus on each section of the diagram below to ensure that each is known, understood, and supports making the process effective. One new addition to this turtle diagram with AS9100 Rev D would be including the risks that are understood for that process and how they are addressed. For a simple process, this could be the completed audit checklist.

- Process effectiveness: As indicated in the turtle diagram, there is an indicator that is used for the process owner to know that the process is running effectively and meeting the objectives and targets that are planned for the process. By comparing this performance indicator against the planned results, the auditor can tell if the process is implemented effectively, or if an improvement is needed in the process to meet the targets.

- Defining samples: It is not often practical or possible to look at every piece of data, which is why the audit process relies on taking a sample to assess the processes. You will want to identify how you will choose your samples, such as randomly from a list of open contracts, as well as how many (hint: you will not want the person being audited to choose your samples to audit).

Why do you need an audit checklist?

Preparation is key for a successful audit, which is why an audit checklist is essential. Many audits have a limited time for you to access the information you need, so you want to know what you are doing before going into the audit area. In addition, if you end up becoming sick and another auditor has to take your place, they need to have enough information to perform the audit in your stead.

It doesn’t matter what format your checklist takes (process diagram, a list of documents to verify for completeness, or a list of questions to ask) – the most important thing to identify is the starting point for the audit. If you find an indication of a problem, you will need to perform further checks (called “following the audit trail”), but your checklist needs to indicate where the audit inquiries start so that you are not doing this during the audit. A professional audit starts with good preparation, which makes it easier to present any corrective actions identified during your audit.

Download a free preview of the AS9100 Premium Documentation Toolkit to see the structure for each document mentioned above.

Mark Hammar

Mark Hammar