Tracey Evans

Tracey Evans

November 4, 2020

Implementation, maintenance, training, and knowledge products for Information Security Management Systems (ISMS) according to the ISO 27001 standard.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

All required policies, procedures, and forms to implement an ISMS according to ISO 27001.

Train your key people about ISO 27001 requirements and provide cybersecurity awareness training to all of your employees.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Compliance and training products for critical infrastructure organizations for the European Union’s Network and Information Systems cybersecurity directive.

All required policies, procedures, and forms to comply with the NIS 2 cybersecurity directive.

Company-wide training program for employees and senior management to comply with Article 20 of the NIS 2 cybersecurity directive.

Compliance and training products for financial entities for the European Union’s DORA regulation.

All required policies, procedures, and forms to comply with the DORA regulation.

Company-wide cybersecurity and resilience training program for all employees, to train them and raise awareness about ICT risk management.

Accredited courses for individuals and DORA professionals who want the highest-quality training and certification.

Compliance and training products for personal data protection according to the European Union’s General Data Protection Regulation.

All required policies, procedures, and forms to comply with the EU GDPR privacy regulation.

Train your key people about GDPR requirements to ensure awareness of data protection principles, privacy rights, and regulatory compliance.

Accredited courses for individuals and privacy professionals who want the highest-quality training and certification.

Implementation, training, and knowledge products for Quality Management Systems (QMS) according to the ISO 9001 standard.

All required policies, procedures, and forms to implement a QMS according to ISO 9001.

Accredited courses for individuals and quality professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 and the QMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for Environmental Management Systems (EMS) according to the ISO 14001 standard.

All required policies, procedures, and forms to implement an EMS according to ISO 14001.

Accredited courses for individuals and environmental professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 14001 and the EMS using Advisera’s proprietary AI-powered knowledge base.

Implementation and training products for Occupational Health & Safety Management Systems (OHSMS) according to the ISO 45001 standard.

All required policies, procedures, and forms to implement an OHSMS according to ISO 45001.

Accredited courses for individuals and health & safety professionals who want the highest-quality training and certification.

Implementation and training products for medical device Quality Management Systems (QMS) according to the ISO 13485 standard.

All required policies, procedures, and forms to implement a medical device QMS according to ISO 13485.

Accredited courses for individuals and medical device professionals who want the highest-quality training and certification.

Compliance products for the European Union’s Medical Device Regulation.

All required policies, procedures, and forms to comply with the EU MDR.

Implementation products for Information Technology Service Management Systems (ITSMS) according to the ISO 20000 standard.

All required policies, procedures, and forms to implement an ITSMS according to ISO 20000.

Implementation products for Business Continuity Management Systems (BCMS) according to the ISO 22301 standard.

All required policies, procedures, and forms to implement a BCMS according to ISO 22301.

Implementation products for testing and calibration laboratories according to the ISO 17025 standard.

All required policies, procedures, and forms to implement ISO 17025 in a laboratory.

Implementation products for automotive Quality Management Systems (QMS) according to the IATF 16949 standard.

All required policies, procedures, and forms to implement an automotive QMS according to IATF 16949.

Implementation products for aerospace Quality Management Systems (QMS) according to the AS9100 standard.

All required policies, procedures, and forms to implement an aerospace QMS according to AS9100.

Implementation, maintenance, training, and knowledge products for consultancies.

Handle multiple ISO 27001 projects by automating repetitive tasks during ISMS implementation.

All required policies, procedures, and forms to implement various standards and regulations for your clients.

Grow your business by organizing cybersecurity and compliance training for your clients under your own brand using Advisera’s learning management system platform.

Accredited Lead Auditor and Implementer courses for DORA and ISO standards and advanced courses to help consultants grow their business, increase recurring revenue, and stand out from bigger competitors.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Find new clients, potential partners, and collaborators and meet a community of like-minded professionals locally and globally.

Implementation, maintenance, training, and knowledge products for the IT industry.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with ISO 27001 (cybersecurity), ISO 22301 (business continuity), ISO 20000 (IT service management), GDPR (privacy), NIS 2 (critical infrastructure cybersecurity), and DORA (cybersecurity for financial sector).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Compliance, training, and knowledge products for essential and important organizations.

Documentation to comply with NIS 2 (cybersecurity), GDPR (privacy), ISO 27001 (cybersecurity), and ISO 22301 (business continuity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for manufacturing companies.

Documentation to comply with ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for transportation & distribution companies.

Documentation to comply with ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for schools, universities, and other educational organizations.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS) and ISO 9001 (QMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, maintenance, training, and knowledge products for telecoms.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with ISO 27001 (cybersecurity), ISO 22301 (business continuity), ISO 20000 (IT service management), GDPR (privacy), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, maintenance, training, and knowledge products for banks, insurance companies, and other financial organizations.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with DORA (cybersecurity for financial sector), ISO 27001 (cybersecurity), ISO 22301 (business continuity), and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for local, regional, and national government entities.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), GDPR (privacy), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS) and ISO 9001 (QMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for hospitals and other health organizations.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (health & safety), NIS 2 (critical infrastructure cybersecurity) and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the medical device industry.

Documentation to comply with MDR and ISO 13485 (medical device), ISO 27001 (cybersecurity), ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (health & safety), NIS 2 (critical infrastructure cybersecurity) and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the aerospace industry.

Documentation to comply with AS9100 (aerospace), ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the automotive industry.

Documentation to comply with IATF 16949 (automotive), ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for laboratories.

Documentation to comply with ISO 17025 (testing and calibration laboratories), ISO 9001 (quality), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and quality professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 and the QMS using Advisera’s proprietary AI-powered knowledge base.

Tracey Evans

Tracey Evans

A corrective action is a mandatory activity for all laboratories accredited to ISO/IEC 17025. It should, however, not be seen as a “rule” or a singular step, but as a core process of an interrelated, functional Quality Management System.

Laboratories often struggle with nonconformances and corrective actions, where they are excessively time-consuming or the chosen corrective action does not achieve the intended result. Furthermore, the level of control is often not proportionate to the impact on quality objectives. Typically, this is because a risk-based approach was not adopted, or inadequate steps were taken.

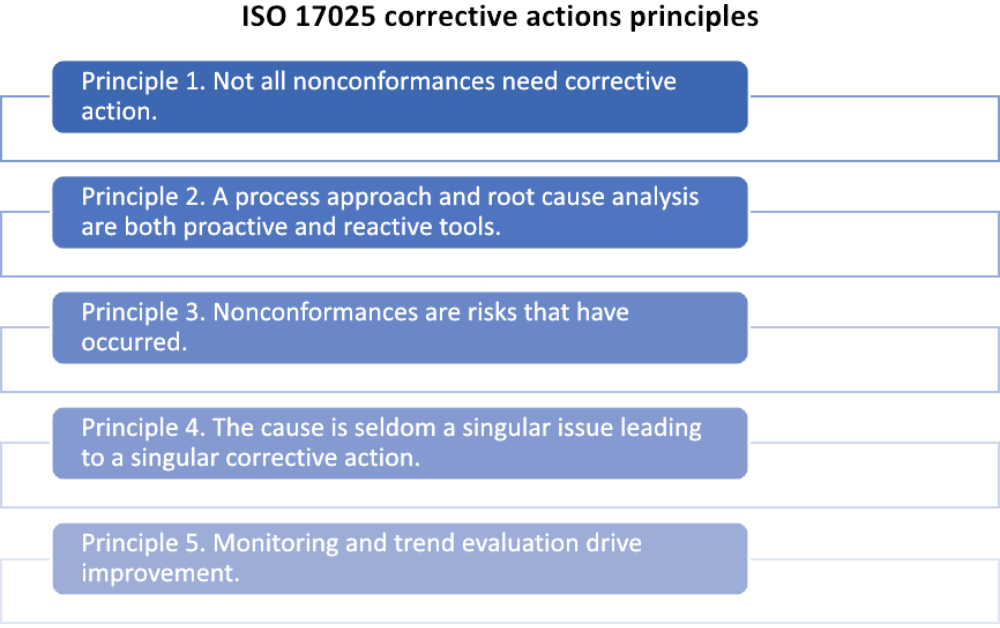

This article provides an overview of applying risk-based thinking to corrective action. It is presented through statements of five risk-based principles and practical steps to improve the handling of nonconformances and root cause analysis to achieve effective corrective actions.

When a laboratory’s results or activities do not conform to its own procedures or customer requirements, the undesired situation is classified as a nonconformance. ISO/IEC 17025:2017 requires laboratories to follow a procedure to handle nonconformances. Where there is doubt about the compliance, or if there is a risk that the nonconforming work could recur, a decision must be made to follow the corrective action procedure. This is nothing new; the same was required in ISO/IEC 17025:2005, the previous version.

What has changed is the requirement for handling corrective actions. There is now no mandatory procedure required and laboratories can decide, based on evaluation, if there is a need for action to eliminate the cause(s) of the nonconformity. This means that laboratories should take a risk-based approach and should implement any action needed (in light of the risk).

The following principles are a foundation for a suitable risk-based approach to corrective actions:

A correction addresses the short-term need, being a remedial reaction to control and correct the nonconformance. Corrections would be applied to every nonconformance. Corrective action, however, taking a risk-based approach, is not always necessary, and in some cases not possible. As the objective is to control the ongoing risk so that the same or a similar problem does not happen again, taking remedial action alone will require justifying the event as an isolated incident or why the current risk level is accepted.

The difficulty for many laboratories is deciding whether correction alone is sufficient.

Application:

Never ignore an event, even if only a correction is necessary. Record it and monitor for any reoccurrence and change in risk level.

There are two primary reactive situations that trigger the need for a corrective action after a correction:

Laboratories will benefit from interlinking a process approach, proactive (risk), and reactive (corrective action) activities.

Application:

Processes should be understood well and mapped, with known inputs and desired outputs for each step. A laboratory should proactively identify risks and put controls in place to reduce the chance of a nonconforming event to an acceptable level.

For those of you familiar with only using the fishbone diagram for root cause analysis, note that it (and other cause-and-effect tools) can also be used for risk assessment. Instead of the effect at the fish head being the problem statement, you state the desired outcome. The causes are the same, using your knowledge of the process.

A well-established management system should have standardized processes, procedures, documentation, and monitoring that provide a level of protection from undesired deviations (something did not happen as it should have) or deficiencies (gaps). Realistically, though, because of the complexity of laboratory operations, risks of nonconforming events will always exist.

A risk register is a valuable tool to help with the evaluation of nonconforming events. Nonconformances fall into two groups:

Application:

If the risk was not identified, consider why not and enter it in the register. If it was identified, review the process steps and prior analysis. Indicate in the register that, due to a nonconformance, the risk levels will be reviewed after the agreed corrective action.

It is often a chain of events that leads to a nonconformance. If a laboratory approaches cause analysis looking for a singular “root cause,” there is an increased risk of ineffective corrective action.

The “root” should be viewed as a system, not a singular ”right answer.” There may be a number of contributory (causal) factors that could be identified during evaluation. These fall into two categories:

Each of these casual factors has a primary reason for happening—its root cause.

Application:

For the laboratory activity and system that have been affected, take the following steps:

Application:

Risks are not static, so actions need monitoring, and risks should be updated after other activities such as audits, client and personnel feedback, and management reviews. Look out for changed risk levels, as well as trends. For example, if many of the nonconformances experienced were previously identified as risks, yet still occurred, it could indicate that controls need improvement.

Taking a more deliberate risk-based approach to corrective actions and root cause analysis is new for many laboratories. What concerns many is defending risk-based decisions during ISO 17025 accreditation assessments.

Adopting and documenting your approach and strategy based on the principles and practical steps introduced in this article should provide the required assurance and drive a more efficient corrective action process.

To implement ISO 17025 easily and efficiently, use our ISO 17025 Documentation Toolkit that provides step-by-step guidance and all documents for full ISO 17025 compliance.

You may unsubscribe at any time. For more information, please see our privacy notice.