Tom Taormina

Tom Taormina

April 15, 2019

Implementation, maintenance, training, and knowledge products for Information Security Management Systems (ISMS) according to the ISO 27001 standard.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

All required policies, procedures, and forms to implement an ISMS according to ISO 27001.

Train your key people about ISO 27001 requirements and provide cybersecurity awareness training to all of your employees.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Compliance and training products for critical infrastructure organizations for the European Union’s Network and Information Systems cybersecurity directive.

All required policies, procedures, and forms to comply with the NIS 2 cybersecurity directive.

Company-wide training program for employees and senior management to comply with Article 20 of the NIS 2 cybersecurity directive.

Compliance and training products for financial entities for the European Union’s DORA regulation.

All required policies, procedures, and forms to comply with the DORA regulation.

Company-wide cybersecurity and resilience training program for all employees, to train them and raise awareness about ICT risk management.

Accredited courses for individuals and DORA professionals who want the highest-quality training and certification.

Compliance and training products for personal data protection according to the European Union’s General Data Protection Regulation.

All required policies, procedures, and forms to comply with the EU GDPR privacy regulation.

Train your key people about GDPR requirements to ensure awareness of data protection principles, privacy rights, and regulatory compliance.

Accredited courses for individuals and privacy professionals who want the highest-quality training and certification.

Implementation, training, and knowledge products for Quality Management Systems (QMS) according to the ISO 9001 standard.

All required policies, procedures, and forms to implement a QMS according to ISO 9001.

Accredited courses for individuals and quality professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 and the QMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for Environmental Management Systems (EMS) according to the ISO 14001 standard.

All required policies, procedures, and forms to implement an EMS according to ISO 14001.

Accredited courses for individuals and environmental professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 14001 and the EMS using Advisera’s proprietary AI-powered knowledge base.

Implementation and training products for Occupational Health & Safety Management Systems (OHSMS) according to the ISO 45001 standard.

All required policies, procedures, and forms to implement an OHSMS according to ISO 45001.

Accredited courses for individuals and health & safety professionals who want the highest-quality training and certification.

Implementation and training products for medical device Quality Management Systems (QMS) according to the ISO 13485 standard.

All required policies, procedures, and forms to implement a medical device QMS according to ISO 13485.

Accredited courses for individuals and medical device professionals who want the highest-quality training and certification.

Compliance products for the European Union’s Medical Device Regulation.

All required policies, procedures, and forms to comply with the EU MDR.

Implementation products for Information Technology Service Management Systems (ITSMS) according to the ISO 20000 standard.

All required policies, procedures, and forms to implement an ITSMS according to ISO 20000.

Implementation products for Business Continuity Management Systems (BCMS) according to the ISO 22301 standard.

All required policies, procedures, and forms to implement a BCMS according to ISO 22301.

Implementation products for testing and calibration laboratories according to the ISO 17025 standard.

All required policies, procedures, and forms to implement ISO 17025 in a laboratory.

Implementation products for automotive Quality Management Systems (QMS) according to the IATF 16949 standard.

All required policies, procedures, and forms to implement an automotive QMS according to IATF 16949.

Implementation products for aerospace Quality Management Systems (QMS) according to the AS9100 standard.

All required policies, procedures, and forms to implement an aerospace QMS according to AS9100.

Implementation, maintenance, training, and knowledge products for consultancies.

Handle multiple ISO 27001 projects by automating repetitive tasks during ISMS implementation.

All required policies, procedures, and forms to implement various standards and regulations for your clients.

Grow your business by organizing cybersecurity and compliance training for your clients under your own brand using Advisera’s learning management system platform.

Accredited Lead Auditor and Implementer courses for DORA and ISO standards and advanced courses to help consultants grow their business, increase recurring revenue, and stand out from bigger competitors.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Find new clients, potential partners, and collaborators and meet a community of like-minded professionals locally and globally.

Implementation, maintenance, training, and knowledge products for the IT industry.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with ISO 27001 (cybersecurity), ISO 22301 (business continuity), ISO 20000 (IT service management), GDPR (privacy), NIS 2 (critical infrastructure cybersecurity), and DORA (cybersecurity for financial sector).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Compliance, training, and knowledge products for essential and important organizations.

Documentation to comply with NIS 2 (cybersecurity), GDPR (privacy), ISO 27001 (cybersecurity), and ISO 22301 (business continuity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for manufacturing companies.

Documentation to comply with ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for transportation & distribution companies.

Documentation to comply with ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for schools, universities, and other educational organizations.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS) and ISO 9001 (QMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, maintenance, training, and knowledge products for telecoms.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with ISO 27001 (cybersecurity), ISO 22301 (business continuity), ISO 20000 (IT service management), GDPR (privacy), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, maintenance, training, and knowledge products for banks, insurance companies, and other financial organizations.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with DORA (cybersecurity for financial sector), ISO 27001 (cybersecurity), ISO 22301 (business continuity), and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for local, regional, and national government entities.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), GDPR (privacy), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS) and ISO 9001 (QMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for hospitals and other health organizations.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (health & safety), NIS 2 (critical infrastructure cybersecurity) and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the medical device industry.

Documentation to comply with MDR and ISO 13485 (medical device), ISO 27001 (cybersecurity), ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (health & safety), NIS 2 (critical infrastructure cybersecurity) and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the aerospace industry.

Documentation to comply with AS9100 (aerospace), ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the automotive industry.

Documentation to comply with IATF 16949 (automotive), ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for laboratories.

Documentation to comply with ISO 17025 (testing and calibration laboratories), ISO 9001 (quality), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and quality professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 and the QMS using Advisera’s proprietary AI-powered knowledge base.

Tom Taormina

Tom Taormina

Those who are invested in Quality Management System implementation and operation may find that understanding its genesis can greatly enhance their ability to be more effective facilitators – especially given that some of you were born after the first version was released in 1987. In this article, you will learn about the forerunner and history of ISO 9000 quality standards and the most important from the series – ISO 9001, which is one of the most widely accepted Quality Management System standards in current use.

World War II devastated most of Europe. Winston Churchill first proposed the concept of a “United States of Europe” in 1946. As treaties evolved and countries rebuilt, they found that there were many aspects of businesses that were incompatible from country to country. Quality standards were very diverse, and the need for a single standard led to the creation of what we now know as ISO 9001.

The quality founding fathers contracted with the International Organization for Standardization to create a non-binding quality standard. ISO, as it is now known, is in the business of writing such standards. Those who remember film cameras know that ISO 100 and ISO 200 are standards for film stock.

Technical Committee 176 (ISO/TC 176) was formed in 1979 to create a universal quality standard. Based on the British Standard BS5750, ISO 9000 was first released in 1987. It was referred to as a “quality assurance standard,” with ISO 9000 being the guidance document. The actual certification standards were divided into three parts:

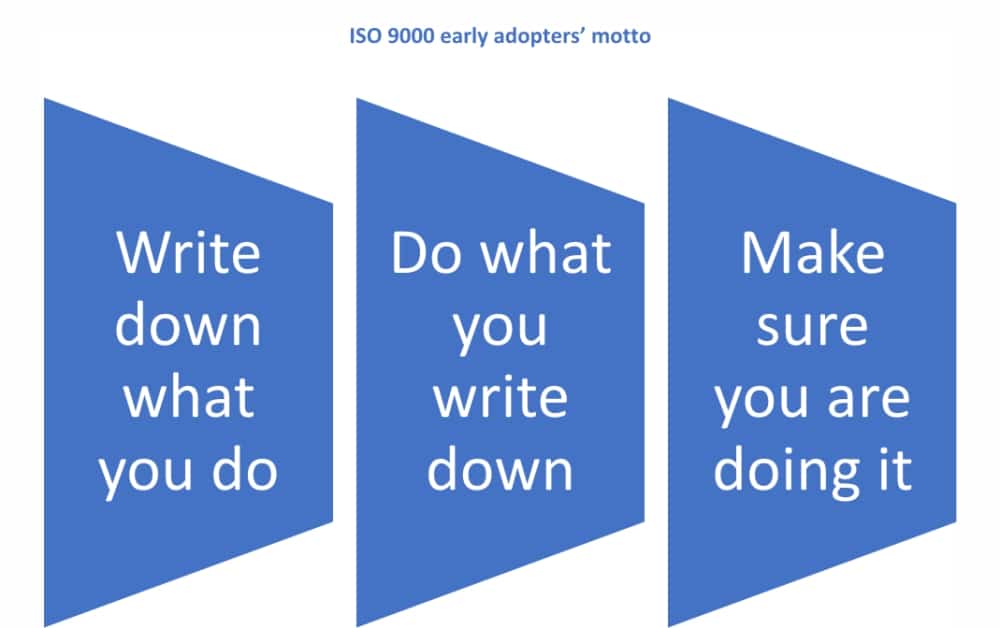

Those of us who were burdened by inflexible military quality standards, such as MIL-Q-9858 and MIL-I-45208, saw the standard as a revolutionary new tool from which to base quality systems that specifically fit their organizational structure and needs. Early adopters created the motto “Write down what you do, do what you write down, and make sure you are doing it” as the easily understood essence of the standard.

“Write down what you do” refers to documenting the processes and their interactions within your organization. “Do what you write down” describes the actions you take to realize your products and services and ensure that they yield the desired outcomes. “Make sure you are doing it” refers to what we know today as QMS auditing. That is, on an ongoing basis, conducting proactive audits to ensure that the processes are effective for their intended use and verify the operator’s ongoing competence.

If the standard was initially intended to be applied universally throughout Europe, what mechanism was necessary to ensure that organizations were actually compliant with it? The governmental bodies that controlled their version/translation of the standard certainly did not want to take on a policing function. That led to the evolution of certification organizations.

Early on, agencies such as the American Bureau of Shipping (ABS) and Det Norske Veritas (DNV) added ISO 9000 certification services to their core businesses of certifying sailing vessels. The national accreditation bodies created a credentialing system for the certification companies to audit and grant certificates of conformance to individual organizations that demonstrated compliance with the standard.

From that beginning, the processes of desk audit, initial certification, periodic surveillance audits, three-year recertification and transition certification evolved into the current formal conformance process.

During the 1990s, ISO 9000 exploded in its adoption and implementation. Because of its universal acceptance, consulting firms and certification services proliferated. Then, entire industries adopted the standard as a basic credential for becoming an approved supplier.

The petrochemical industry was an early adopter, and Houston, Texas, became the epicenter of ISO 9000 implementation. I facilitated ISO 9001 and ISO 9002 implementations across Texas, trained internal auditors, and wrote three guidance books for ABS Government Institutes, the consulting arm of ABS QE, the certification body.

The American Society for Quality (ASQ) devoted extensive resources to helping organizations with standards implementation and training. I chaired the Quality Management Systems Committee of ASQ and helped develop the foundation for the body of knowledge for the current ASQ certifications, such as CMQ/OE and CQA.

Along with the widespread implementation of the standard, professional organizations blossomed, and entire conferences were convened on the topic of quality management. TC 176 gathered vast amounts of data on implementation techniques and auditing practices. They also found that the 1987 standard was developing controversy and confusion as it was implemented in a wide variety of countries, industries, and organizations.

There was also strife about the early adopters interpreting “write down what you do” as documenting everything in the organization. As a result, many organizations became paper mills of manuals, procedures, and forms.

TC 176 did have a plan for revising the standard approximately every five years, but the amount of data to be studied and the differing opinions on interpretations and acceptance criteria became overwhelming. I sat in on one session where the entire debate was over the meaning of “continuous” and “continual” as they relate to the standard. It seems that neither word translates well into German or French.

The outcome of the TC 176 continual improvement process led to the following revisions:

1994. The first revision emphasized preventive action and made a first attempt at slowing down the documentation paper mill.

2000. The second revision was a complete rewrite and did away with the three separate standards. It focused on process management instead of reactive quality assurance and quality control. It placed a higher burden on senior management to integrate quality management into business management.

2008. This revision introduced clarifications from the ongoing work of TC 176 and began harmonization with ISO 14001:2004.

2015. Another complete rewrite of the standard, this version introduced a new era of Quality Management Systems. It suggested replacing preventive action with risk-based thinking. Further, it created a focus on business performance instead of quality metrics and greatly streamlined the required documentation.

To learn more about the latest ISO 9001 revision, check out this Infographic: ISO 9001:2015 vs. 2008 revision – What has changed?

There are varying statistics, but there were more than 1.3 million ISO 9001 certificates in effect at the end of 2014 in 190+ countries around the globe.

Having a better understanding of the history, perhaps some of you will contribute evolutionary input to the 2020 revision.

Each revision of ISO 9001 has focused more on the success of the organization, rather than on the tools of quality management. The more we can contribute to business success, the more valuable will be the contribution of Quality Management Systems.

To comply with all ISO 9001 requirements, use this helpful ISO 9001 Premium Documentation Toolkit that provides all QMS documents.

You may unsubscribe at any time. For more information, please see our privacy notice.