With the release of AS9100 Rev D, the requirements from the International Aerospace Quality Group (IAQG) for creating and implementing an aerospace Quality Management System (QMS), we can now see what has really changed in the new version.

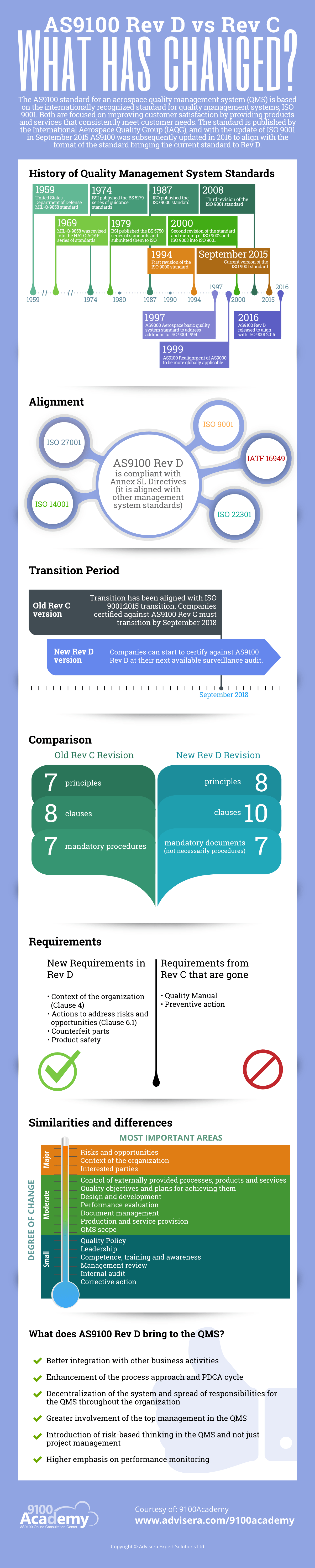

History of Quality Management System standards

The first QMS standards can be traced back to 1959 with the release of the United States Department of Defense MIL-Q-9858 standard. This was later adapted in 1979 into the BS 5750 series of standards from BSI, which were subsequently proposed to ISO in 1979. With the release of ISO 9001:1994, the aerospace industry decided to incorporate this into a Quality Management System requirements document that included specific requirements for aviation, space, and defense organizations. In 1997, AS9000 was released, incorporating the requirements of ISO 9001:1994. In 1999, AS9100 was released to realign AS900 for a more global market. The most recent and currently available version of AS9100, revision D, was released in 2016 to align with the latest release of ISO 9001:2015.

Alignment

The new version of AS9100 is aligned with Annex SL, which makes it more compatible with other management system standards that have been released by the ISO organization, such as ISO 14001, ISO 22301, ISO 27001, and ISO 20000. This commonality between the standards makes the integration of more than one management system even easier.

Transition period

Companies that are currently certified against the AS9100 Rev C must complete the transition to AS9100 Rev D by September 2018. This may seem like a long time, but some lead certification bodies have already stopped issuing new certifications against the AS9100 Rev C standard, and will soon stop issuing re-certification against this previous revision. Now is the time to act, because time is quickly running out.

Comparison

The essence of the quality management principles behind the standard have remained the same, with the addition of the concept of risk-based thinking, which affects risks that exist for your QMS. The change in the number of clauses is to align with Annex SL as mentioned above, and the movement away from mandatory procedures is intended to provide more freedom in how documentation works for companies implementing the standard. This can be a little confusing, but can help you in the long run.

Requirements

There are a few new requirements, the most significant of which are Context of the organization (Clause 4) and Actions to address risks and opportunities (Clause 6.1). These requirements help to incorporate everyday business practices into the QMS. New requirements specific to the aerospace industry are regarding counterfeit parts (Clause 8.1.4) and product safety (Clause 8.1.3). Some requirements that have been removed include the quality manual and preventive action; however, these can be retained if the organization finds them useful. See also: AS9100: Understanding the requirements of context of the organization.

Similarities and differences

Not all changes are as significant as others; some bring a lot of change, while others are only slightly different. Those with major change include Risks and opportunities, Context of the organization, and Interested parties, which are new requirements that need to be done from scratch. Implementing these requirements may shine a whole new light on your QMS.

Those with moderate changes include Control of externally provided processes, products and services; Quality objectives and plans for achieving them; Performance evaluation; Document management; Production and service provision; and QMS Scope. These will need to be reviewed and updated as necessary.

Clauses with only minor changes include Quality Policy; Leadership; Competence, training and awareness; Management review; Internal audit; and Corrective action. These processes have only slight changes, and most of the existing QMS related to these requirements will likely remain unchanged.

What does AS9100 Rev D bring to the QMS?

The new revision of AS9100 has brought a number of significant changes to the QMS that will affect how quality management is approached in organizations. These changes will, however, improve your QMS by providing:

- better integration with other business activities

- enhancement of the process approach and PDCA cycle

- decentralization of the system and spread of responsibilities for the QMS throughout the organization

- greater involvement of the top management in the QMS

- introduction of risk-based thinking in the QMS

- more emphasis on performance monitoring

Most importantly, the new revision of AS9100 gives us a chance to take a step back and review how the QMS is implemented within our organization and make changes that will lead to improvement. Now is the time to seize this opportunity to make your QMS better.

To implement AS9100 easily and efficiently, use our AS9100 Documentation Toolkit that provides step-by-step guidance and all documents for full AS9100 compliance.

Mark Hammar

Mark Hammar