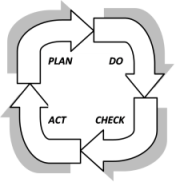

We know that one of the main goals of an ISO 13485 Quality Management System (QMS) is continual improvement. But, does that mean improvement of our individual processes? Or, should we focus on overall improvement of the system? The answer is yes, and yes. By applying the Plan-Do-Check-Act (PDCA) approach, you can think of your individual processes as being small parts of one large cycle of improvement, thereby focusing the improvement of each process toward the overall improvement of your company.

Where does Plan-Do-Check-Act come from?

PDCA is a cycle that was originally created by Walter Shewhart (one of the fathers of modern quality control), and later popularized by Edward Deming (the other founding father). The premise is that a cycle for implementing change, when followed and repeated, will result in successive improvements in the process to which it was applied.

Here is an example that we can all probably relate to – when you choose a wireless carrier, you:

- PLAN to have perfect performance, with no dropped calls, outages, or other problems.

- DO start using the wireless service.

- CHECK and monitor the actual performance, and note that the service is not so perfect.

- ACT on the situation, whether that means accepting the service as it is, calling customer service to try to resolve the problem, or canceling your service and trying another provider.

The difference between “fixing” a problem and following the PDCA cycle is that PDCA is a model for sustained, continual improvement over the life of your process. That is why PDCA is so easily applied to the ISO 13485 standard, as its main goal is continual improvement of the QMS.

How Plan-Do-Check-Act is described in ISO 13485 requirements

The introduction to the ISO 13485 standard, in section 0.3, includes an explanation of the process approach and its importance to the implementation of an ISO 13485-compliant Quality Management System. Additionally, a note mentions the application of the Plan-Do-Check-Act methodology to all processes, with a graphic offering a basic overview of how the ISO 13485 requirements fit into the PDCA cycle. Let me explain how the PDCA improvement cycle is applied to the QMS, with the applicable clause numbers of the standard appearing in parentheses.

Plan – One of the most important parts of the QMS is planning of quality objectives (5.4.1) and of the quality system (5.4.2), which will ultimately be used to monitor the QMS and its processes (4.2.1 d). Next comes leadership commitment to lead the organization toward a greater customer focus by creating a quality policy and defining organizational roles and responsibilities (5.1, 5.2, & 5.3). This is followed by the identification of risks and opportunities within the QMS, and addressing them accordingly, as well as setting quality objectives and planning changes in support of continual improvement (7.1). The last step of this phase is to determine and implement the support structure necessary to execute your plans, which will include planning resources (6.1), identifying competencies (6.2), raising awareness (6.3), setting up communications (6.3), and establishing processes for the creation and control of required documentation (4.2).

Do – All of this prior planning means nothing unless you actually carry out these plans. Operational controls must be identified for the QMS, as well as product and/or service requirements (7.2.1). Designs must be developed (7.3), and controls must be implemented for any externally provided products, services, and processes (8.4). The production process must be set up with controls for product and service release (8.5 & 8.6), and any nonconformities in products or services must be dealt with (7.5.1). To sum it all up, each task involved in the creation and provision of products and/or services to your customers must be completed.

Check – A number of requirements in the standard specify the need to assess the QMS processes to make sure they are functioning as planned. This will involve monitoring, measuring, analyzing, and evaluating your products and/or services to confirm that they meet the requirements, that the processes are suitable and effective, and that customer service goals are achieved (8.2.2). A key method for assessing the effectiveness of the QMS is an internal audit of its processes (8.2.4); in addition, management review of the collected data should be performed to identify any issues and to plan for any necessary changes (5.6).

Act – Now is the time to address whatever issues may have arisen during the Check step. Improvement (8.5) is the name of the game, and the actions steps will need to include addressing nonconformity through corrective and preventive actions (8.5.2 & 8.5.3) prevent and treat nonconformities.

Plan – Yes, we’ve completed one cycle, so now we’re ready to start again and put plans in place to ensure further improvement. The internal audit findings during the Check phase may have necessitated action steps during the Act phase. If so, you’ll need to make changes during this Plan phase to meet the new requirements in the following Do phase. The management review will take into account the results of the internal audit, as well as any corrective actions taken, to provide planned resources to support the necessary changes. On an ongoing basis, resources will be reassessed, and then increased, decreased, or reassigned according to changing business needs. This, of course, will lead us to another Do phase, and on through the cycle.

Use the PDCA cycle to ensure continual improvement of your QMS

The purpose of Quality Management System is to continually strive for improvements in the company, because such improvement is the only way the company will continue to compete in today’s increasingly competitive market. By following the PDCA cycle, your company can focus the processes and objectives of the QMS toward overall improvement, leading to increased efficiency and cost savings that can be put toward further improvement. And that is a win-win for both the company, and its customers.

To comply with all ISO 13485 requirements, use this helpful ISO 13485 Documentation Toolkit that provides QMS documents for medical device companies.

Waqas Imam

Waqas Imam