To obtain a CE mark for your medical device under the MDR (Medical Device Regulation), you must demonstrate biocompatibility. The update in November 2025 introduced significant changes that you should be aware of. There is a shift away from merely adding more tests toward a more traceable and exposure-driven risk management process aligned with ISO 14971. This update includes clearer guidance on exposure and stronger expectations for justifying materials and chemistry. As a result, what previously met the standards may now require a different and better-documented approach.

ISO 10993-1:2025 shifts biocompatibility from a “matrix exercise” to a risk management workflow: Explicitly consider reasonably foreseeable misuse, calculate exposure using “contact days,” use contact-specific biological effects tables, and strengthen materials/chemical evidence to justify (and sometimes reduce) biological testing.

What is ISO 10993 and why it matters

ISO 10993 is the core standard series for biological evaluation (biocompatibility) of medical devices. It defines how to assess and document biological risks from device materials in contact with the body, using a risk-based and exposure-informed approach rather than a fixed checklist of tests.

Under the EU Medical Device Regulation (MDR), biological safety evidence is essential for technical documentation during conformity assessments. You cannot demonstrate compliance or obtain a CE mark for patient-contacting medical devices without an adequate ISO 10993-based biological evaluation, which may include testing or a scientifically justified rationale.

See also: EU MDR Technical Documentation Guide

Its official name is ISO 10993-1:2025, and this 6th revision was published in 2025, replacing the revision from 2018.

ISO 10993 is directly relevant to ISO 13485 because biological evaluation activities (planning, supplier/material controls, verification, technical documentation, and change control) must be implemented and maintained within the Quality Management System. It also integrates with ISO 14971 by requiring biological risks to be evaluated and justified within overall risk management.

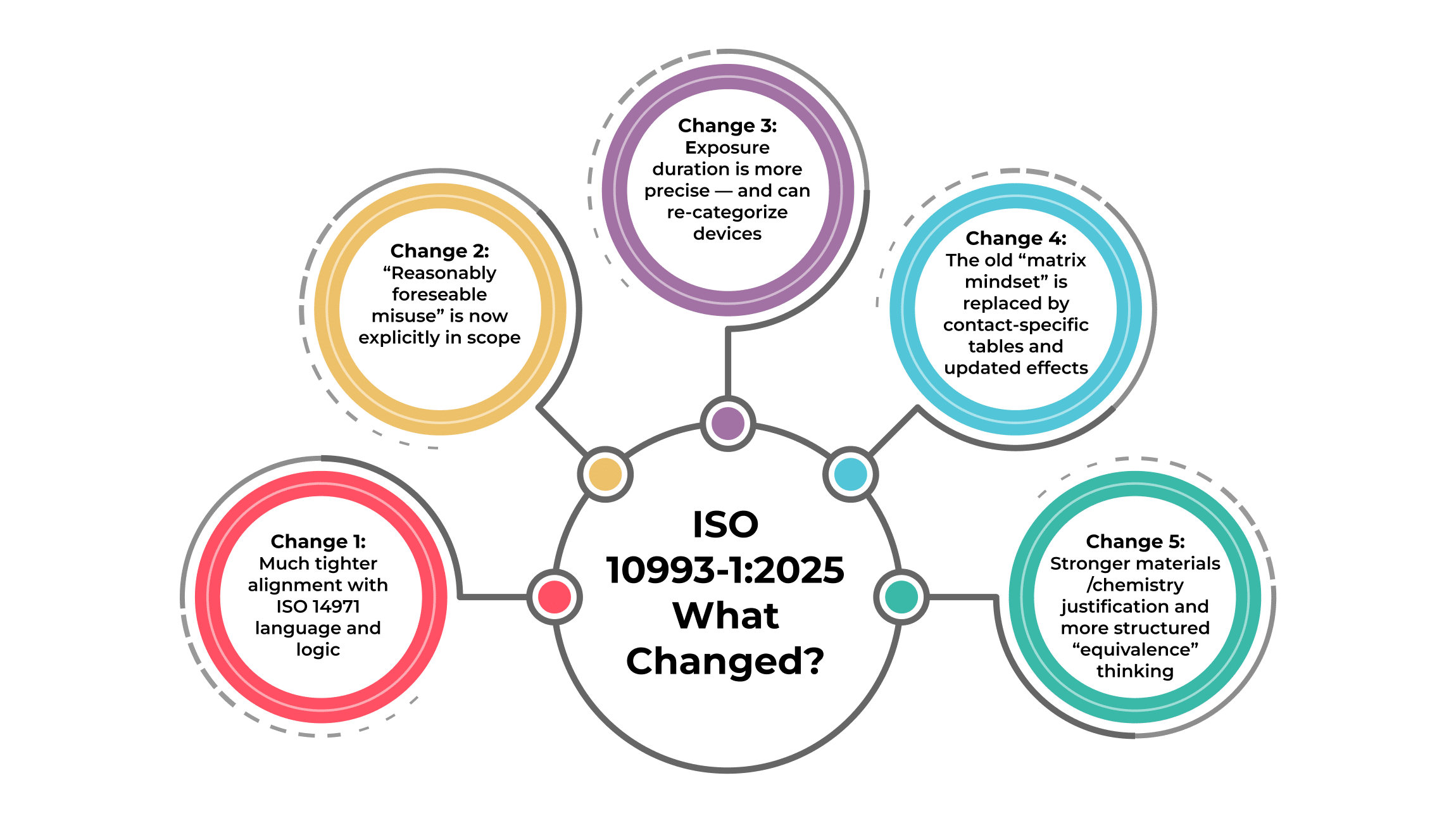

Here are the five main changes in this 2025 revision that we will analyze further in the text:

- Much tighter alignment with ISO 14971 language and logic.

- “Reasonably foreseeable misuse” is now explicitly in scope.

- Exposure duration is more precise — and can re-categorize devices.

- The old “matrix mindset” is replaced by contact-specific tables and updated effects.

- Stronger materials/chemistry justification and more structured “equivalence” thinking.

Change #1: Much tighter alignment with ISO 14971 language and logic

The 2025 revision pushes biological evaluation deeper into a risk management structure: Terminology and steps look more like ISO 14971, with a clearer focus on the progression from biological hazards to hazardous situations to harms, and expectations for biological risk estimation and biological risk control. It adopts ISO 14971 language and flows more directly: Identify biological hazards, define biologically hazardous situations, define biological harms, perform biological risk estimation and evaluation, and document risk control and lifecycle updates.

Learn more here: Steps in ISO 14971 risk management for medical devices

Imagine a wearable patch that comes into contact with the skin. Under a matrix mindset, teams often stop at irritation/sensitization and cytotoxicity. Under a risk management mindset, you also write down the story:

- Hazard: Adhesive chemicals may leak into the environment.

- Hazardous situation: Prolonged skin contact and sweat/heat increases release.

- Harm: Localized dermatitis or systemic exposure may occur if specific chemicals are involved.

- Controls include material selection, extraction limits, instructions for use (IFU), wear-time limits, and supplier controls.

- Evidence should consist of chemical characterization, a toxic risk assessment, and targeted tests if necessary.

Reviewers seek traceability of materials, as well as information on harm exposure and controls.

Change #2: “Reasonably foreseeable misuse” is now explicitly in scope

ISO 10993-1:2025 requires biological evaluations to consider the intended use and reasonably foreseeable misuse, focusing on realistic and predictable scenarios that may alter exposure or contact conditions.

Reasonably foreseeable misuse refers to a situation where users, whether patients or professionals, utilize a medical device in a plausible but incorrect manner that alters exposure or contact conditions, potentially affecting biological safety and biocompatibility.

Most misuse examples fall into these buckets:

- Longer or more frequent use than intended (e.g., leaving dressings on for days, wearing braces overnight)

- Wrong body site or contact environment (e.g., using a skin-only device on broken skin, using an external device internally)

- Incorrect cleaning/disinfection/reprocessing (e.g., reusing single-use devices, using harsher chemicals, or using the wrong sterilization method)

- Wrong assembly or non-approved accessories (e.g., off-brand gels/adhesives/tubing, mixed components, incorrect setup causing new tissue contact)

- Using damaged devices (e.g., cracked silicone, torn packaging)

- Home-use conditions that increase chemical release (e.g., heat/sweat, lotions/ointments under wearables)

In ISO 10993-1:2025 terms, these misuses matter because they can change contact type, duration (“contact days”), frequency, or chemical exposure, which may change which biological effects you must address and how you justify your evidence.

Change #3: Exposure duration is more precise — and can re-categorize devices

One of the most practical updates is exposure counting. The 2025 revision emphasizes concepts like daily contact and total exposure period based on calendar days — even if contact is brief on a given day.

If your previous rationale was based on simply adding up minutes or hours of use, it’s time to reassess using the new definitions and ensure that your selected biological effects still hold. Consider a device that is used for 10 minutes each day over a span of 10 days, such as a therapy applicator or a patient-use accessory. From an “hours” perspective, one might argue that the total usage is 100 minutes, which could be classified as short contact. However, with the “contact day” approach, you would count this as 10 contact days. In this case, your total exposure period is determined by the number of days from the first use to the last, rather than by minutes.

This is how teams get surprised: The device remained the same, but the categorization logic changed. Now, your Biological Evaluation Plan (BEP) must explain why the biological effects coverage is still adequate.

Change #4: The old “matrix mindset” is replaced by contact-specific tables and updated effects

The former Annex A table approach has been replaced by separate tables within the main text, which map various contact types (e.g., skin, mucosa, breached/internal tissue, blood) to relevant biological effects that should be considered. This is more than simple formatting; it compels you to clarify how the device interacts with the body and the biological implications of that contact.

A single “device-level category” can hide this nuance. With the new contact-specific tables, you’ll often document multiple contact types and justify biological effects accordingly, rather than selecting one broad category and calling it done.

Consider a suction drain with:

- an external tube that touches intact skin, and

- an internal segment contacting breached tissue

Change #5: Stronger materials/chemistry justification and more structured “equivalence” thinking

The summary from ISO highlights that materials characterization has become a strengthened area of focus. Industry analyses indicate that there is an expectation for you to more explicitly integrate physical and chemical information, along with toxicology considerations, into biological risk analysis. This integration is often necessary to justify whether certain testing is required or not.

For example, you have a legacy surgical instrument handle made from a long-used polymer, but you are changing only the colorant supplier. A weak argument might be: “It’s the same polymer family; no new risks are expected.” A stronger argument, in line with ISO 10993-1:2025 standards, would be as follows:

- Define key biological factors: Identify what is important biologically, including contact type and duration, patient population, sterilization methods, and processing residues.

- Conduct chemical characterization or supplier evidence review: Focus this analysis on the changes made, particularly the composition of the colorant and the potential risks associated with extractables.

- Perform a gap analysis: Determine which endpoints are already covered by existing data and what aspects could be affected by the colorant change, and explain why the residual risk remains acceptable.

This structured justification often helps teams reduce unnecessary animal testing while still satisfying regulatory reviewers.

What to do now: A practical update path for your BEP/BER

If you have existing files based on ISO 10993-1:2018, a sensible approach to upgrading is as follows:

- Revise the front-end logic so that the Biological Evaluation Plan (BEP) and Biological Evaluation Report (BER) follow a clear risk management narrative, including the progression from hazards to harms to risk, and finally to controls.

- Reassess exposure by using daily contact and total exposure period assumptions. Be sure to document your assumptions clearly.

- Align your information with the updated biological effects tables for each relevant contact type; avoid relying solely on a legacy “matrix selection.”

- Include foreseeable misuse scenarios that realistically increase exposure or alter contact conditions.

- Enhance the chemistry and materials section, ensuring that your decisions regarding “no new testing” are supported by a documented gap analysis.

Conclusion

ISO 10993-1:2025 is no longer focused primarily on “more testing”; it emphasizes improved reasoning. The biological evaluation is now structured to function like risk management, with clearer expectations regarding exposure (contact days), potential misuse, and justification of materials and chemistry.

Here are two key points to remember:

- Your Biological Evaluation Plan (BEP) or Biological Evaluation Report (BER) should clearly tell a traceable risk story that includes hazards, harms, risks, controls, and conclusions.

- Reassess the duration of exposure using contact day logic, as this can significantly impact categorization and the biological effects you need to address.

See our ISO 13485 & MDR Premium Documentation Toolkit for step-by-step guidance and ready-to-use templates to align biocompatibility with ISO 14971.

Kristina Zvonar Brkic

Kristina Zvonar Brkic