You’ve probably heard that ISO 9001 is being revised, but you may still be wondering: What exactly is changing, and what does it mean for your organization? This article will guide you through the key updates in ISO 9001:2026, and show you how to turn these revisions into practical actions that strengthen daily operations and improve results.

ISO 9001:2026 won’t be a revolution, but companies that prepare early will turn compliance into improvement. The new draft emphasizes leadership, culture, risk and opportunity management, change planning, knowledge management, and customer communication. Success depends less on updating documents and more on embedding these changes into daily decisions and behaviors — using the transition as a chance to build a stronger, more resilient QMS.

Short summary of main differences

The ISO DIS 9001:2025 introduces changes in the following areas:

- Leadership & Culture – Leadership must foster a culture of quality and ethical behavior (5.1.1).

- Awareness – Awareness now encompasses values and culture, in addition to procedures (7.3).

- Communication – Customers must be informed about contingency plans (8.2.1).

- Risk & Opportunity Management – Risks and opportunities must be analyzed and evaluated, not just listed, and opportunities deserve more attention (6.1).

- Planning Changes – Clause 6.3 requires effectiveness, communication, and review when implementing changes.

- Knowledge Management – Knowledge must be retained, applied, and shared, and now extends beyond ensuring product conformity (7.1.6).

- Operations & Supply Chain – Suppliers must align with the requirements of customers and interested parties, not just technical specifications (8.4).

- Property belonging to customers or external providers – Although the wording to protect customer property is less strict, the expectation stays the same (8.5.3).

- Performance Evaluation – Customer satisfaction uses multiple channels (9.1.2); audits need clear objectives (9.2); management reviews must consider changes in interested parties and ensure that outputs are linked to continual improvement (9.3).

- Continual Improvement – Clause 10.1 requires ensuring the suitability, adequacy, and effectiveness of the Quality Management System, not just fixing problems.

See a more detailed breakdown here: ISO 9001:2015 vs. ISO DIS 9001:2025 – Main differences.

Implementing the changes clause by clause

Clause 5.1.1 – Leadership and commitment

Top management must foster a culture of quality and ethical behavior, which is evident in their daily choices. When leaders prioritize long-term quality over short-term gains — investing in preventive maintenance, funding training, or refusing to compromise on supplier ethics — they set the tone. By following the same procedures they expect from others, rewarding ethical problem-solving, and being transparent with stakeholders, leadership demonstrates that quality and ethics are nonnegotiable. Employees mirror this behavior: Procurement applies the same ethical standards in negotiations, engineers recognize that testing and compliance take precedence over speed, and the organization as a whole learns that integrity drives performance.

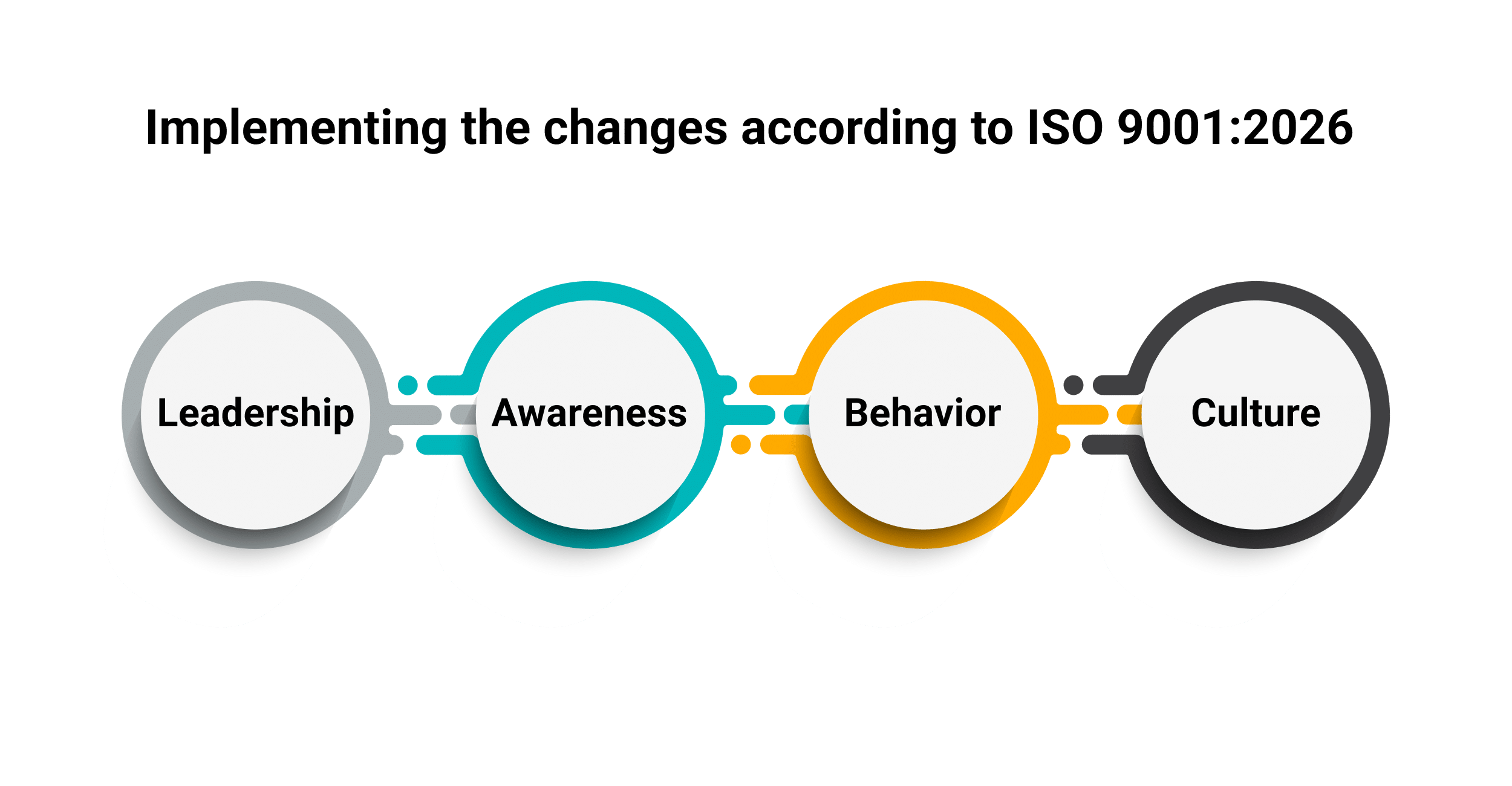

Culture, therefore, works as a chain reaction:

Leaders set the tone, awareness ensures that everyone understands what is expected, and awareness then guides decisions. Over time, consistent behaviors shape the culture that customers and interested parties recognize.

See more in: To what extent should top management be involved in your QMS?

Clause 6.1 – Risks and opportunities

A major change is that organizations are now expected to go beyond simply determining risks and opportunities; they must also analyze and evaluate them. For SMEs, this may sound like a big step, but it can be kept simple. Many companies were already doing this, especially those following Advisera’s practical guidance.

Opportunities deserve the same discipline as risks. This shift emphasizes that opportunities are no longer just “nice to have” ideas on the side; they are strategic tools that must be managed systematically to add value and drive continual improvement.

For example, a small manufacturer considering automation or a customer self-service portal should assess benefits, resources, and risks — ensuring that opportunities are managed with the same rigor as risks to deliver real impact.

See more in: How to address risks and opportunities in ISO 9001.

Clause 6.3 – Planning changes

Clause 6.3 on planning changes is more demanding. In the past, the primary requirement was to control changes so that quality was not compromised. Now organizations must explicitly consider effectiveness, communication, and review.

When changing the layout of a production line, for example, planning should include:

- Effectiveness: Define how success will be measured, such as reduction in cycle time, improved material flow, or fewer handling errors. Track these indicators once the new layout is in use.

- Communication: Inform operators about the reasons for the change, update work instructions, and brief logistics staff and maintenance teams. Encourage employees to provide suggestions during the transition.

- Review: After three months, conduct a workshop on the shop floor to evaluate what has improved, identify where bottlenecks remain, and determine what further adjustments are still needed.

These steps align with recognized change management practices and transform clause 6.3 into a practical framework for smoother, more successful transitions.

See more in: QMS Change Management in 7 steps.

Clause 7.1.6 – Organizational knowledge

Knowledge management now goes beyond product conformity: It must support all QMS results, from compliance to customer satisfaction and improvement. Knowledge retention means capturing critical know-how so it isn’t lost when people leave or projects close — through lessons learned, knowledge repositories, or succession planning. However, knowledge only adds value when it is applied and shared. It needs to influence decisions and workflows, not just sit in documents. Practices such as updating work instructions, briefing teams, or utilizing communities of practice ensure that knowledge flows across the organization, prevents rework, and drives improvement. For example, when a production line is redesigned, lessons are captured (retained), instructions updated (applied), and shifts briefed (shared) so the benefits spread and stick.

See more in: How to manage knowledge of the organization according to ISO 9001.

Clause 7.3 Awareness

Awareness requirements also grow. Employees must understand the organization’s quality culture, ethical standards, and procedures. This can be reinforced through onboarding, refresher sessions, and recognizing employees who act with integrity.

See more in: ISO 9001 awareness training material: How to create it, what it should contain.

Clause 8.2.1 Customer communication

Customer communication is also updated. Clause 8.2.1 requires organizations to inform customers about contingency plans in the event of disruptions. This may involve posting updates on websites, using FAQs, or providing timely information through social media. For example, a small electronics company introduced a customer portal that not only provides technical documentation but also hosts announcements about planned downtime and service updates.

See more in: How the ISO 9001:2015 standard can help improve relationships with your customers.

Clause 8.4 – Control of externally provided processes, products and services

Organizations must now ensure that external providers understand not only the technical specifications but also the requirements of customers and other interested parties. This may involve updating supplier manuals, contracts, or purchase orders to include expectations for ethical behavior, sustainability, and customer interaction.

At the same time, documented information must clearly specify characteristics, activities, and results to avoid ambiguity in operations. For SMEs, a simple one-page checklist or visual work instruction might be sufficient.

See more in: How to create beneficial supplier partnerships in ISO 9001.

Clause 8.5.3 – Property belonging to customers or external providers

Although the wording to protect customer property is less strict, the expectation stays the same. Items provided by customers still need to be identified, protected, and controlled.

A logistics provider recently updated its supplier manual to reflect these changes. In addition to delivery requirements, it also added guidelines on safety, environmental practices, and driver behavior when interacting with customer staff. The manual also includes a checklist for parcel integrity and scanning at checkpoints. Meanwhile, returned goods are clearly labeled and securely stored until they are collected.

See more in: How does ISO 9001 property clause 8.5.3 reflect on software?

Clause 9.1.2 Customer satisfaction

Monitoring customer satisfaction now requires using multiple feedback sources, including modern ones such as online reviews and social media, if applicable.

See more in: Main elements of handling customer satisfaction in ISO 9001.

Clause 9.2 Internal audit

Internal audits must have defined objectives. Instead of repeating routine checklists, audits should target specific goals; for example, testing the effectiveness of supplier controls or checking how well employees understand ethical standards.

See more in: Five Main Steps in ISO 9001 Internal Audit.

Clause 9.3 Management review

Management reviews must explicitly consider changes in interested parties and ensure that outputs are linked to continual improvement. An SME in medical devices, for example, added “changes in interested parties’ expectations” as a permanent agenda item. This led to prioritizing faster delivery and launching a logistics improvement project.

See more in: How to make Management Review more useful in the QMS.

Clause 10.1 Improvement (General)

Clause 10.1 clarifies that continual improvement must address the suitability, adequacy, and effectiveness of the QMS. This goes beyond fixing problems. It requires asking: Does our system still fit our business model?

One packaging company adopted this approach by reviewing suitability (Does the QMS support new eco-friendly products?), adequacy (Are new supplier certifications covered?), and effectiveness (Are customers consistently satisfied?). This resulted in the redesign of processes, updating of supplier controls, and enhancement of feedback mechanisms.

Continual improvement is no longer a once-a-year agenda item. It is a discipline that ensures that the QMS evolves alongside the business.

See more in: ISO 9001 vs. Six Sigma: How they compare and how they are different.

Practical steps to implement the changes

The draft is evolutionary, not revolutionary — but it still requires preparation. The best way to prepare is to focus on a few practical steps that address the main areas of change:

- Begin with a gap analysis against the draft requirements.

- Update leadership practices, awareness training, and communications to reflect the emphasis on culture and ethics.

- Review how risks and opportunities are analyzed, how changes are planned, and how audits are designed.

- Adjust management reviews to explicitly consider the changes and improvement outputs of interested parties.

Two key points stand out. First, implementation is about integration into daily work, not just updating documents. These changes only matter if they shape how people make decisions, manage risks and opportunities, and interact with customers.

Second, starting early provides time to improve, not just comply. Organizations that prepare now can use the transition to build a stronger, more resilient QMS.

Order the ISO 9001 Premium Documentation Toolkit now and get a free upgrade to the 2026 revision when it’s released.

Carlos Pereira da Cruz

Carlos Pereira da Cruz