John Nolan

John Nolan

August 29, 2017

Implementation, maintenance, training, and knowledge products for Information Security Management Systems (ISMS) according to the ISO 27001 standard.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

All required policies, procedures, and forms to implement an ISMS according to ISO 27001.

Train your key people about ISO 27001 requirements and provide cybersecurity awareness training to all of your employees.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Compliance and training products for critical infrastructure organizations for the European Union’s Network and Information Systems cybersecurity directive.

All required policies, procedures, and forms to comply with the NIS 2 cybersecurity directive.

Company-wide training program for employees and senior management to comply with Article 20 of the NIS 2 cybersecurity directive.

Compliance and training products for financial entities for the European Union’s DORA regulation.

All required policies, procedures, and forms to comply with the DORA regulation.

Company-wide cybersecurity and resilience training program for all employees, to train them and raise awareness about ICT risk management.

Accredited courses for individuals and DORA professionals who want the highest-quality training and certification.

Compliance and training products for personal data protection according to the European Union’s General Data Protection Regulation.

All required policies, procedures, and forms to comply with the EU GDPR privacy regulation.

Train your key people about GDPR requirements to ensure awareness of data protection principles, privacy rights, and regulatory compliance.

Accredited courses for individuals and privacy professionals who want the highest-quality training and certification.

Implementation, training, and knowledge products for Quality Management Systems (QMS) according to the ISO 9001 standard.

All required policies, procedures, and forms to implement a QMS according to ISO 9001.

Accredited courses for individuals and quality professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 and the QMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for Environmental Management Systems (EMS) according to the ISO 14001 standard.

All required policies, procedures, and forms to implement an EMS according to ISO 14001.

Accredited courses for individuals and environmental professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 14001 and the EMS using Advisera’s proprietary AI-powered knowledge base.

Implementation and training products for Occupational Health & Safety Management Systems (OHSMS) according to the ISO 45001 standard.

All required policies, procedures, and forms to implement an OHSMS according to ISO 45001.

Accredited courses for individuals and health & safety professionals who want the highest-quality training and certification.

Implementation and training products for medical device Quality Management Systems (QMS) according to the ISO 13485 standard.

All required policies, procedures, and forms to implement a medical device QMS according to ISO 13485.

Accredited courses for individuals and medical device professionals who want the highest-quality training and certification.

Compliance products for the European Union’s Medical Device Regulation.

All required policies, procedures, and forms to comply with the EU MDR.

Implementation products for Information Technology Service Management Systems (ITSMS) according to the ISO 20000 standard.

All required policies, procedures, and forms to implement an ITSMS according to ISO 20000.

Implementation products for Business Continuity Management Systems (BCMS) according to the ISO 22301 standard.

All required policies, procedures, and forms to implement a BCMS according to ISO 22301.

Implementation products for testing and calibration laboratories according to the ISO 17025 standard.

All required policies, procedures, and forms to implement ISO 17025 in a laboratory.

Implementation products for automotive Quality Management Systems (QMS) according to the IATF 16949 standard.

All required policies, procedures, and forms to implement an automotive QMS according to IATF 16949.

Implementation products for aerospace Quality Management Systems (QMS) according to the AS9100 standard.

All required policies, procedures, and forms to implement an aerospace QMS according to AS9100.

Implementation, maintenance, training, and knowledge products for consultancies.

Handle multiple ISO 27001 projects by automating repetitive tasks during ISMS implementation.

All required policies, procedures, and forms to implement various standards and regulations for your clients.

Grow your business by organizing cybersecurity and compliance training for your clients under your own brand using Advisera’s learning management system platform.

Accredited Lead Auditor and Lead Implementer courses for ISO standards and DORA, and an advanced course to help consultants grow their business.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Find new clients, potential partners, and collaborators and meet a community of like-minded professionals locally and globally.

Implementation, maintenance, training, and knowledge products for the IT industry.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with ISO 27001 (cybersecurity), ISO 22301 (business continuity), ISO 20000 (IT service management), GDPR (privacy), NIS 2 (critical infrastructure cybersecurity), and DORA (cybersecurity for financial sector).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Compliance, training, and knowledge products for essential and important organizations.

Documentation to comply with NIS 2 (cybersecurity), GDPR (privacy), ISO 27001 (cybersecurity), and ISO 22301 (business continuity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for manufacturing companies.

Documentation to comply with ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for transportation & distribution companies.

Documentation to comply with ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for schools, universities, and other educational organizations.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS) and ISO 9001 (QMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, maintenance, training, and knowledge products for telecoms.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with ISO 27001 (cybersecurity), ISO 22301 (business continuity), ISO 20000 (IT service management), GDPR (privacy), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, maintenance, training, and knowledge products for banks, insurance companies, and other financial organizations.

Automate your ISMS implementation and maintenance with the Risk Register, Statement of Applicability, and wizards for all required documents.

Documentation to comply with DORA (cybersecurity for financial sector), ISO 27001 (cybersecurity), ISO 22301 (business continuity), and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and security professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 and the ISMS using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for local, regional, and national government entities.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), GDPR (privacy), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS) and ISO 9001 (QMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for hospitals and other health organizations.

Documentation to comply with ISO 27001 (cybersecurity), ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (health & safety), NIS 2 (critical infrastructure cybersecurity) and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the medical device industry.

Documentation to comply with MDR and ISO 13485 (medical device), ISO 27001 (cybersecurity), ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (health & safety), NIS 2 (critical infrastructure cybersecurity) and GDPR (privacy).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 27001 (ISMS), ISO 9001 (QMS), and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the aerospace industry.

Documentation to comply with AS9100 (aerospace), ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for the automotive industry.

Documentation to comply with IATF 16949 (automotive), ISO 9001 (quality), ISO 14001 (environmental), and ISO 45001 (health & safety), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 (QMS) and ISO 14001 (EMS) using Advisera’s proprietary AI-powered knowledge base.

Implementation, training, and knowledge products for laboratories.

Documentation to comply with ISO 17025 (testing and calibration laboratories), ISO 9001 (quality), and NIS 2 (critical infrastructure cybersecurity).

Company-wide cybersecurity awareness program for all employees, to decrease incidents and support a successful cybersecurity program.

Accredited courses for individuals and quality professionals who want the highest-quality training and certification.

Get instant answers to any questions related to ISO 9001 and the QMS using Advisera’s proprietary AI-powered knowledge base.

John Nolan

John Nolan

Most companies who have a QMS (Quality Management System) certified according to ISO 9004 or ISO 9001:2015 are accustomed to performing against set objectives and KPIs (key performance indicators), and also demonstrating continual improvement, which we examined in the article ISO 9001 – Where does quality management fit into your organization? But, how can the QMS itself, and its effectiveness, be measured, and is there any one method of doing this that will provide an organization’s top management with one true indicator of QMS performance?

Section 9.1.1 of the ISO 9001:2015 standard suggests that “the organization shall evaluate the performance and the effectiveness of the quality management system.” While this is not prescriptive in terms of measuring the QMS by one true indicator, most top management teams prefer that one true measure is established to ascertain the effectiveness of the system, as well as whether month-on-month improvement – and value for money – are attained. You can find more details on this from the article Monitoring and measurement: The basis for evidence-based decisions. So, if you are a quality professional given that task, where do you begin, and what criteria should you consider?

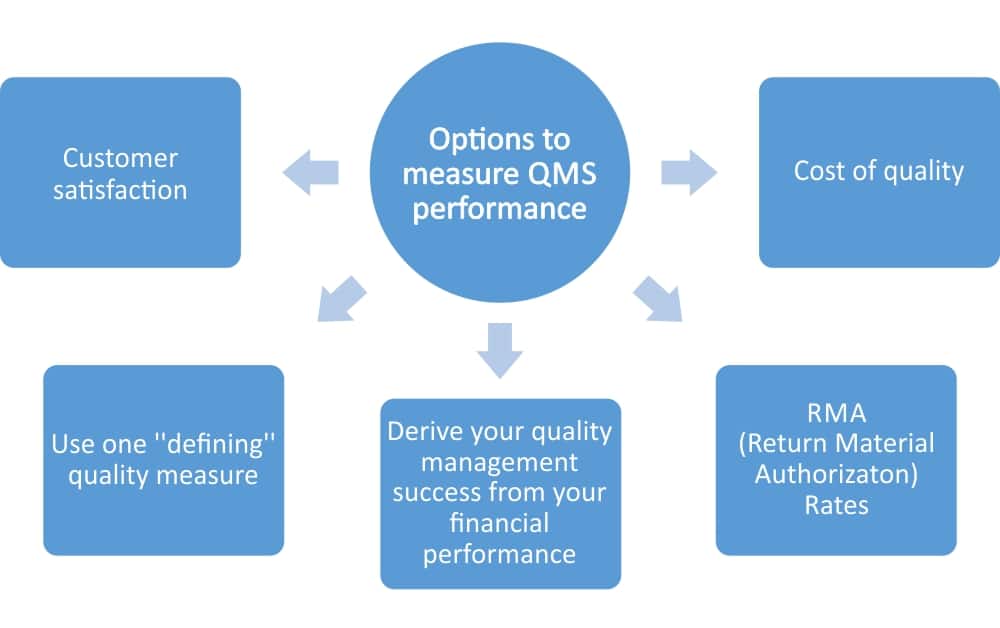

There have been many opinions over the years on how quality is best measured, particularly in manufacturing processes, although with the increase in service industries in recent years this has also become a point of discussion there. Manufacturing organizations traditionally may like to use measures such as “defects per million opportunities,” while a service organization may choose to measure customer satisfaction via a survey. Each organization must decide what is most important to it, but let us consider some of the options available to measure QMS performance:

Every organization must decide what works best for them, but personally, I like to measure the “cost of quality” as a primary QMS specifically for a manufacturing organization, supported by all the other options above measured at a secondary level. You can refer to the article Analysis of data obtained from Monitoring and Measurement to help here, too. That way, the true “cost of quality” can be presented to top management in dollar form, which usually gives the incentive to drive initiatives from a strategic level. At a secondary level, using elements such as customer feedback, internal test fails, and RMA analysis will help you to improve your “cost of quality,” while also protecting your customers and improving the processes that design and deliver your product. In this way, you can ensure continual improvement, customer satisfaction, and improved product design – all elements that validate good QMS performance – and your board of directors can be satisfied that they have one “true” measure that informs them as to how the QMS is performing, and can be easily used to ascertain if continual improvement is occurring.

To implement ISO 9001 easily and efficiently, use our ISO 9001 Premium Documentation Toolkit that provides step-by-step guidance and all documents for full ISO 9001 compliance.

You may unsubscribe at any time. For more information, please see our privacy notice.