Probably the most misunderstood concept in the design requirements of ISO 9001, if not the entire standard, is the difference between Design Verification and Design Validation. These two steps are distinctly different, and important in a good design process. One step is used to make sure that the design has addressed every requirement, while the other is used to prove that the design can meet the requirements set out for it.

ISO 9001 Design Verification and Design Validation are two steps that are distinctly different, and important in a good design process. Verification is used to make sure that the design has addressed every requirement, while validation is used to prove that the design can meet the requirements set out for it.

Design and Development Verification

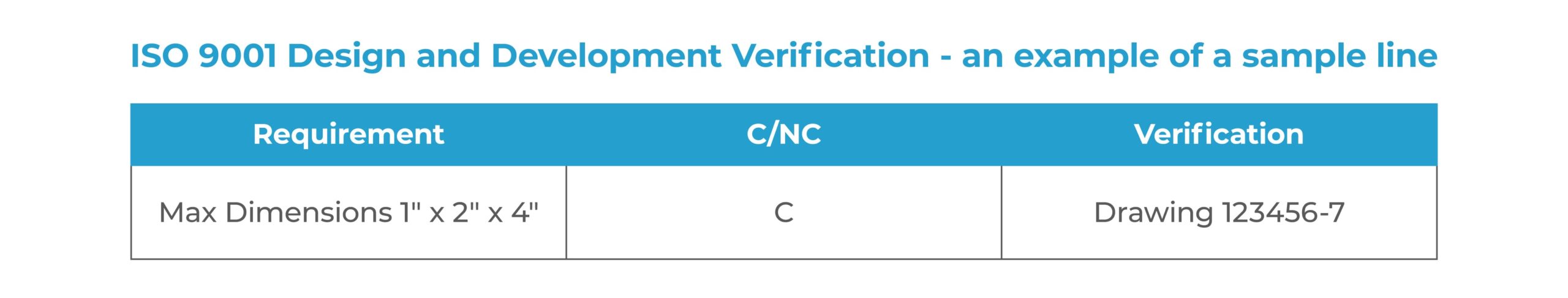

Verification is strictly a paper exercise. It starts with taking all the design inputs: specifications, government and industry regulations, knowledge taken from previous designs, and any other information necessary for proper function. With these requirements in hand you compare to your design outputs: drawings, assembly instructions, test instructions, and electronic design files.

In the comparison you are ensuring that each requirement in the inputs is accounted for in the outputs. Is each required test called out in the test instructions, including the correct pass/fail criteria for each test? Are all product acceptance criteria correct? Are all physical characteristics identified in the build instructions?

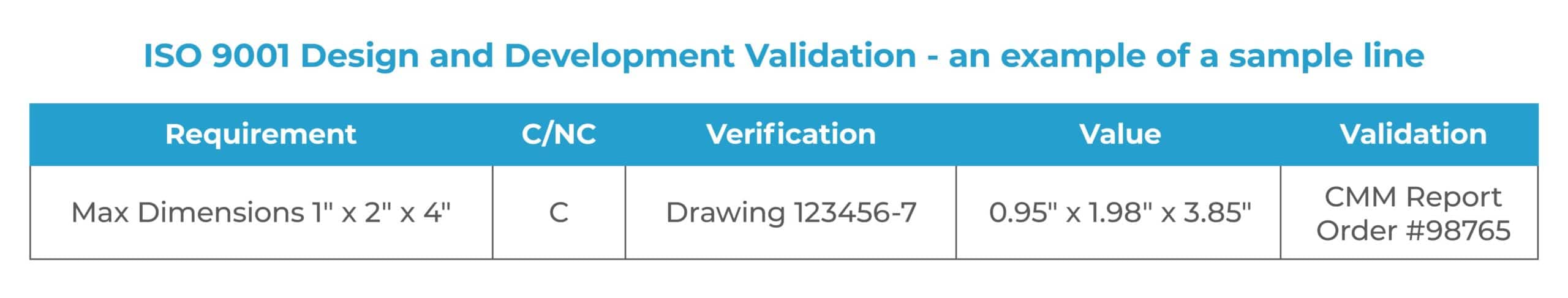

The output of this verification review is often recorded in a Statement of Compliance document. This document will list every requirement for the design, identify if the design is compliant or not, and list where this compliance is proven in the documentation.

Design and Development Validation

Validation is the step where you actually build a version of the product, and would be done against the requirements as modified after verification. This does not necessarily mean the first production unit, but it can. It can also be an engineering model, which some companies use to prove the first run of a complicated new design, or it can be a portion of the design which is different from a previous model, when the design is a modification of an already-proven design. Once you decide what representative product you will build to prove the design, you fully test it to make sure that the product, as designed, will meet all the necessary requirements defined in the Design Inputs.

This will often require more testing that will be used on production models. To ensure that all requirements are met, a full set of measurement and tests is done on the validation unit. In some industries this is referred to as a First Article Inspection (FAI), a first off, or Production Part Approval Process (PPAP). Depending on customer requirements this can be recorded as a standalone document, or an addition to the Statement of Compliance created in the verification step.

After validation, the full set of requirements on one unit of most products can have a reduced level of inspection and testing, depending on factors such as requirements criticality or manufacturing process capability. A good product validation can help decide which requirements need to be checked on every product, and which do not.

Verification vs Validation – Satisfying Customer Needs

Each of these steps is important in the design process because they serve two distinct functions. Verification is a theoretical exercise designed to make sure that no requirements are missed in the design, whereas validation is a practical exercise that ensures that the product, as built, will function to meet the requirements. Together, they ensure that the product designed will satisfy the customer needs, and the needs of the customer are one of the key focuses for ISO 9001 and improving Customer Satisfaction.

To comply with all ISO 9001 requirements, use this helpful ISO 9001 Premium Documentation Toolkit that provides all QMS documents.

Mark Hammar

Mark Hammar